Pipe bursting is a modern method used in the field of trenchless rehabilitation for the replacement of existing pipelines.

This technique is particularly beneficial for replacing old or damaged pipes without the need for extensive excavation.

It is an efficient, cost-effective, and environmentally friendly approach to updating underground utilities.

The Evolution of Pipe Replacement Techniques

Historically, replacing underground pipes involved extensive digging, causing significant disruption to the surrounding environment and daily life.

Over time, trenchless technologies like pipe bursting have revolutionized the process, minimizing surface disturbance and reducing the project’s impact on the community.

Understanding the Pipe Bursting Process

Basic Mechanism

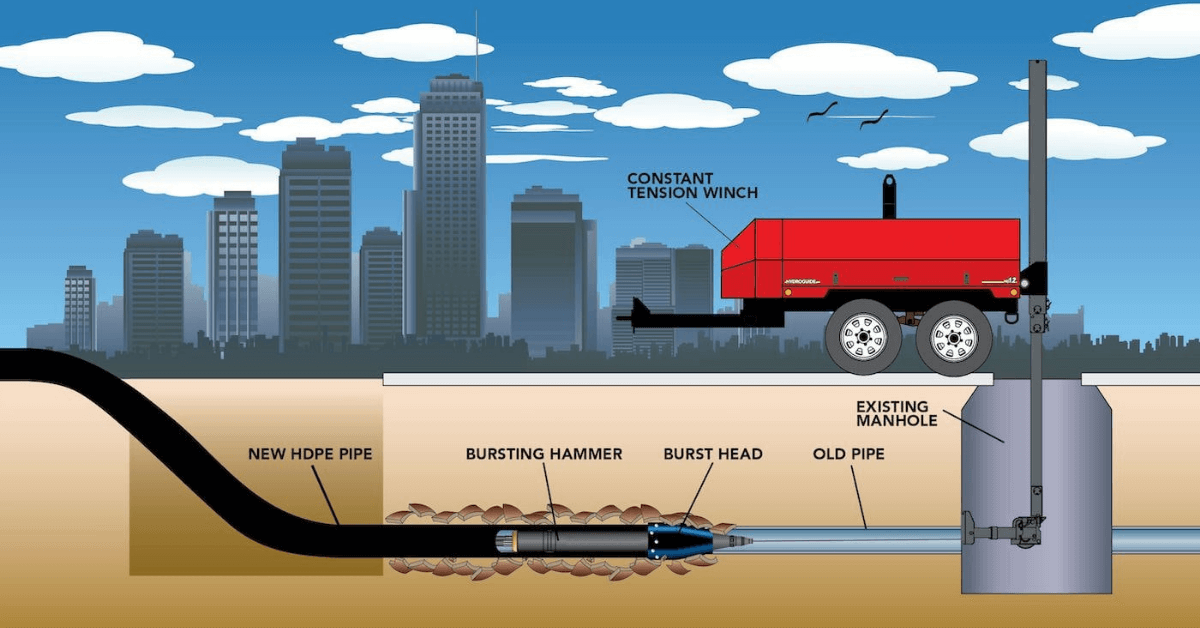

The pipe bursting process involves breaking apart an existing pipe while simultaneously pulling a new pipe into place.

This is achieved by using a bursting head, which is larger in diameter than the old pipe.

The head is pulled through the existing pipe, breaking it apart and pushing the fragments into the surrounding soil.

Equipment Involved

Key equipment in pipe bursting includes the bursting head, pulling rods, a hydraulic power pack, and the new pipe.

The bursting head is often equipped with blades or rollers to break the old pipe effectively. The pulling rods are used to guide and pull the bursting head through the old pipe.

Types of Pipes That Can Be Burst

Pipe bursting is versatile and can replace various types of pipes, including clay, concrete, cast iron, and PVC.

The new pipe, often made of high-density polyethylene (HDPE), is flexible, durable, and resistant to corrosion and root intrusion.

Advantages of Pipe Bursting

Reduced Environmental Impact

One of the most significant benefits of pipe bursting is the reduced environmental impact. The technique minimizes surface disruption, preserving landscaping, roadways, and nearby structures.

This aspect is particularly important in urban areas where excavation can be highly disruptive.

Cost-Effectiveness

Pipe bursting is often more cost-effective than traditional excavation methods. It reduces the need for extensive digging, labor, and equipment, and the quicker completion time further reduces costs.

Versatility and Efficiency

This method is versatile, allowing for the replacement of pipes in various sizes and materials. It is also efficient, capable of replacing long stretches of pipe in a relatively short period.

Challenges and Considerations in Pipe Bursting

Soil Conditions

Soil conditions play a critical role in the success of pipe bursting. In certain types of soil, such as very dense or rocky soils, the process can be more challenging.

Existing Infrastructure

Care must be taken to avoid damaging existing underground utilities, such as gas lines or electrical cables. Accurate mapping and identification of these utilities are crucial.

Pipe Size and Material

The size and material of the existing pipe can affect the feasibility of the bursting process. Larger or more robust pipes may require more powerful equipment.

Best Practices in Pipe Bursting

Thorough Planning

Successful pipe bursting projects require careful planning. This includes assessing the existing pipeline, soil conditions, and surrounding infrastructure.

Proper planning ensures that the project is carried out safely and efficiently.

Skilled Operators

The operation of the equipment requires skilled personnel. Trained and experienced operators can ensure the process is performed correctly and safely.

Compliance with Regulations

Adhering to local regulations and industry standards is crucial. This ensures that the project is compliant with safety and environmental guidelines.

Conclusion

Pipe bursting represents a significant advancement in the field of pipeline rehabilitation. It offers an efficient, cost-effective, and environmentally friendly solution for replacing old or damaged pipes.

As technology and techniques continue to evolve, pipe bursting is likely to become an even more popular choice for infrastructure upgrades.